"Please discard this one and buy another machine" is what the technician said.

Part 1:

Mr Bharath Kumar who is a Founder-Member of @repaircafecollectiveindia happens to be on the board of the hospital which had a faulty microscope in the O.T. He would not throw but always try to fix it.

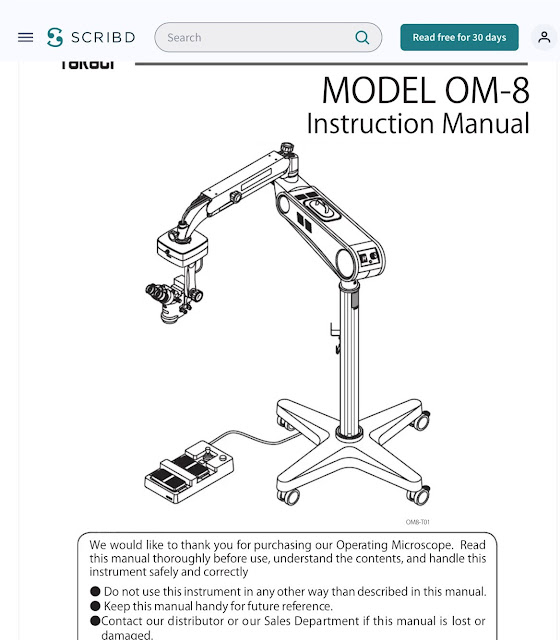

The machine was a 20-year-old Japanese one. The doctors had used it for many complex surgeries but now the "focus" function of the microscope was non-functional.

Technicians' advice notwithstanding Mr Bharath Kumar decided to call in Mr Jithendran T. K. who was a comrade in-arms in @repaircafecollectiveindia.

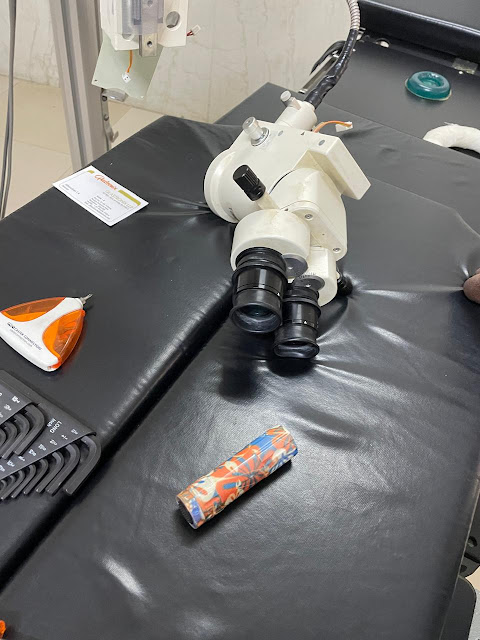

The two gentlemen were thorough tinkerers but they hadn't worked in the sanitized environs of an O.T. On being assured that they could feel at home as the O.T. would be sanitized afterwards in any case, they got down to work.

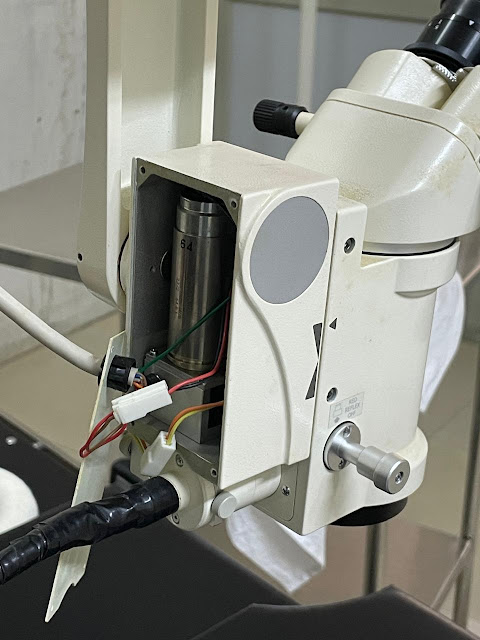

They figured that there are 2 motors in the microscope: one for the "zoom function" and one for the "focus function". Also, they noticed that both motors were working. The motors are operated by the surgeon using a foot pedal. However, for "focus-function" even though the motor was rotating there was no lens movement.

While opening the machine was challenging as there were very minute parts, putting it back together would be even more challenging.

Having opened the microscope they figured that the motor that was meant for the "focus function" had a defect in the gear transmission as the rotary movement of the motor was not transferred to the lens assembly. They found that the locking mechanism of the gear on the motor shaft was loose and it required tightening. Tightening the gear back onto the motor shaft would fix the problem.

.jpeg)

.jpeg)

.jpeg)

What was interesting, is that this Japanese machine had a Swiss-built motor for "focus function". Mr Jithendran T. K. remarked, being familiar with such Japanese-made machines, that they would have sourced a motor that would be the "best-in-class" in those days and no less. So the chances of the motor going bad would be less indeed.

.jpeg)

.jpeg)

.jpeg)

While assembling the microscope, they were excited to try out their "fix". When the motor worked and the microscope focused, it was a huge sense of satisfaction and achievement for the two tinkerers.

.jpeg)

A Japanese machine, that can be used in the O.T. of a hospital costs upwards of 10 to 15 Lakhs INR in the present times and a simple "fix" like this could save them a big amount that can be used to treat needy people that the Charitable Hospital did. The machine could now function for the next 10 to 15 years at least serving the people it was originally purchased to serve.

This experience shows how the skill of tinkering and working with parts of simple and complex machines, helps save money as well as prevents another addition to the waste dump.

Not to mention the sense of pride and achievement for having "fixed" such a problem.

.jpeg)

A Japanese machine, that can be used in the O.T. of a hospital costs upwards of 10 to 15 Lakhs INR in the present times and a simple "fix" like this could save them a big amount that can be used to treat needy people that the Charitable Hospital did. The machine could now function for the next 10 to 15 years at least serving the people it was originally purchased to serve.

This experience shows how the skill of tinkering and working with parts of simple and complex machines, helps save money as well as prevents another addition to the waste dump.

Not to mention the sense of pride and achievement for having "fixed" such a problem.

Part:2

During the process of "fixing" the microscope Mr Jithendran T.K. noticed that one of the halogen bulbs in the O.T. was not working. Determined to "fix" this relatively simpler problem he opened the unit to discover that the transformer used to power the bulbs in the overhead unit was defective.

To support a cost-effective dimming mechanism for the T lights, the manufacturer developed a product-specific transformer to address this requirement. This however made the serviceability ( removal of the transformer assembly) challenging as well as not easy to reach without a ladder.

Mr Jithendran T.K. had to have this transformer taken back to his factory for rewinding to rectify the issue. However, when the transformer was installed, it was found that the dimmer unit was defective. The defective dimmer unit was bypassed to confirm the functioning of the transformer, which proved to be fine.

Now the dimmer unit has been removed and taken for repair/ diagnosis. The dimming function is important for the surgeons to help identify the different tissues and organs by adjusting the O T lamp brightness.

Presently that dimmer switch is being tinkered with to help get the O.T. lights back in working condition.

so the process of maintenance goes on...

During the process of "fixing" the microscope Mr Jithendran T.K. noticed that one of the halogen bulbs in the O.T. was not working. Determined to "fix" this relatively simpler problem he opened the unit to discover that the transformer used to power the bulbs in the overhead unit was defective.

To support a cost-effective dimming mechanism for the T lights, the manufacturer developed a product-specific transformer to address this requirement. This however made the serviceability ( removal of the transformer assembly) challenging as well as not easy to reach without a ladder.

Mr Jithendran T.K. had to have this transformer taken back to his factory for rewinding to rectify the issue. However, when the transformer was installed, it was found that the dimmer unit was defective. The defective dimmer unit was bypassed to confirm the functioning of the transformer, which proved to be fine.

Now the dimmer unit has been removed and taken for repair/ diagnosis. The dimming function is important for the surgeons to help identify the different tissues and organs by adjusting the O T lamp brightness.

Presently that dimmer switch is being tinkered with to help get the O.T. lights back in working condition.

so the process of maintenance goes on...

...............................................................................................................................................................

the skill of tinkering and working with parts of simple and complex machines, helps save money as well as prevents another addition to the waste dump

.......................................................................................................................................................................................................................................................................................

-This article is authored by Himadri Das who is an urbanist and bicycle repair enthusiast. He is a professor of urban planning at Cept University

.jpg)

Comments

Post a Comment